1、 The use of fiber laser cutting machines can shorten processing time and improve processing efficiency. Due to the fact that in the production process, it takes a lot of time and effort to complete the processing of a part within one minute. Fiber laser cutting machine can directly process the material of the workpiece into the desired shape by cutting the workpiece, thereby reducing processing time.

2、 The use of fiber laser cutting machines can also improve work efficiency. Most fiber laser cutting machines on the market are used in the metal material cutting industry. In the process of metal processing, it is necessary to cut metal raw materials. If you want to quickly complete all the cutting processes, you can choose a fiber laser cutting machine to save labor to the greatest extent, shorten the production cycle of the workpiece, and improve work efficiency.

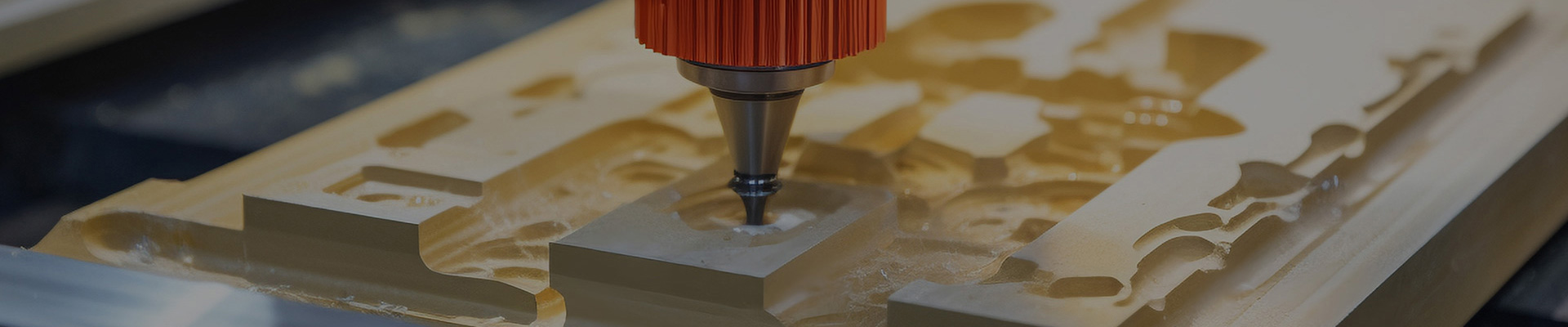

3、 The use of fiber laser cutting machines can achieve high-quality processing. When cutting, the laser beam will focus into small light points, achieving high power density at the focal point. The material will be quickly heated to the degree of vaporization, evaporating to form pores. When the beam of light moves linearly with the material, the hole continuously forms narrow seams. Laser cutting of workpieces has high precision, fast speed, good quality, and smooth cutting surface without burrs.

Jinan Rongchi CNC Machinery Co.,LTD

Address: Daqiao Street Office, Tianqiao District, Jinan City, Shandong Province

Phone: +86-13156006758

Email: rongchigroup@rcskcnc.com

Website: www.rcskcnc.com

Copyright By © Rongchi CNC Machinery