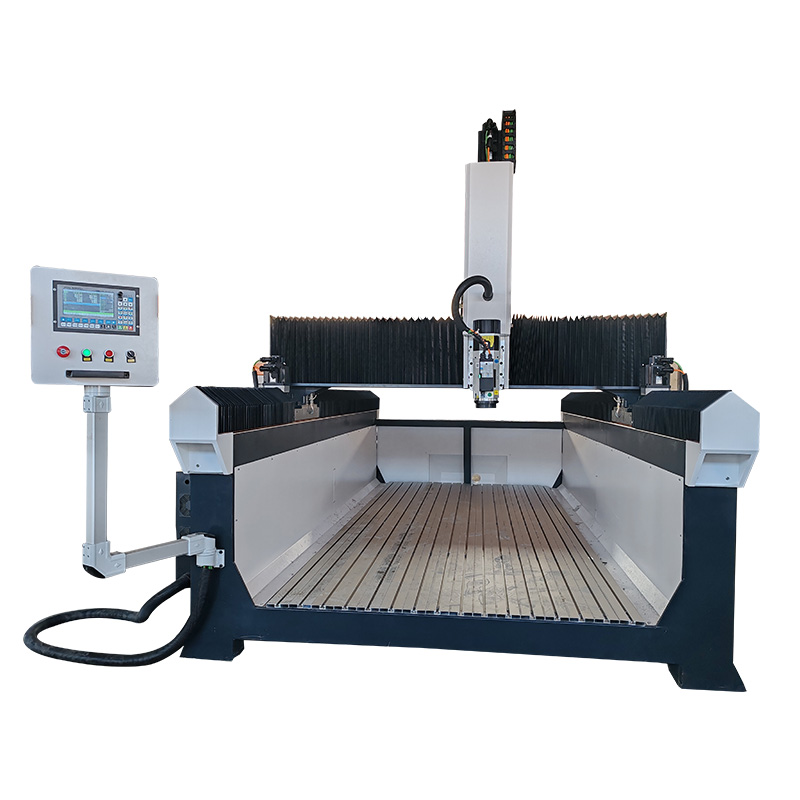

RC1325/1530/1830/2040

Model:RC1325/1530/1830/2040

Spindle power:Water cooling4.5-7.5KW / Air cooling 6-9KW

Spindle speed :12000-18000rpm

Spindle bore:¢32mm

Loading size:500-800mm

Driver:Leadshine/Eura/KND/Yaskawa

Voltage:AC380V/50Hz

Command:G-code F/S command compatible

Model:RC1325/1530/1830/2040

Spindle power:Water cooling4.5-7.5KW / Air cooling 6-9KW

Spindle speed :12000-18000rpm

Spindle bore:¢32mm

Loading size:500-800mm

Driver:Leadshine/Eura/KND/Yaskawa

Voltage:AC380V/50Hz

Command:G-code F/S command compatible

| Specification | Parameters | |

| Model | RC1325/1530/1830/2040 | |

| Working size | X axis | 1300mm-2000mm |

| Y axis | 2500mm-4000mm | |

| Z axis | 500mm-800mm | |

| Structure | Table | Aluminium+Rubber sheet/ Steel |

| X、Y、Z | X、Y axis rack-pinion, Z axis ball screw | |

| Speed | Traveling speed | 15000mm/min |

| Working speed | 10000mm/min | |

| Spindle power | Water cooling4.5-7.5KW / Air cooling 6-9KW | |

| Spindle speed | 12000-18000rpm | |

| Spindle bore | ¢32mm | |

| Loading size | 500-800mm | |

| Driver | Leadshine/Eura/KND/Yaskawa | |

| Voltage | AC380V/50Hz | |

| Command | G-code F/S command compatible | |

| Control system | Taiwan Syntec/Weihong/KND | |

| Weight | 2-5Tons |

Application:

Mold industry: Used to carve all type of molds, automotive molds, vesel wooden molds,aircraft wooden molds,propeller modls,train wooden molds.

Musical industry:Used for large musical instrument 3D curve surface,shape cutting work.

Sculpture industry:Welding supplies,film and television props.

Performance:

◆EPS styrofoam carving machine,all spare parts choose famous brand.

◆Adopts with water cooling high power electrical spindle or air cooling spindle,Japanese Yaskawa servo motor and planetary reducer.

◆Intelligent protection working table, prevent misoperation or software mistake caused table damage,intelligent machining boundary protection,

prevent machinery collision because of designing oversize.

◆Taiwan Syntec control system,auto completion of multiple layers 3D carving&cutting ,fast and smooth 。

◆Imported 4 rows steel balls, widen Hiwin linear orbit,automatic lubrication.Equal force on all direction ensure machining accuracy and strength.

Jinan Rongchi CNC Machinery Co.,LTD

Address: Daqiao Street Office, Tianqiao District, Jinan City, Shandong Province

Phone: +86-13156006758

Email: rongchigroup@rcskcnc.com

Website: www.rcskcnc.com

Copyright By © Rongchi CNC Machinery